en

en

Plate Heat Exchangers designed to your technical specification

Looking for a reliable heat transfer solution?

We offer custom-engineered plate heat exchangers designed to match your specific project requirements.

As an official distributor of premium Danish equipment, we ensure top quality, outstanding energy efficiency, and fast factory-direct delivery.

Share your project details and receive a personalized quote.

Why choose KONTECH

Tailored approach

We work closely with each client to deliver customized heat exchanger solutions that meet their specific project requirements and ensure optimal performance.

High quality

Plate heat exchangers are fully certified and comply with international quality and safety standards, ensuring reliable performance and long service life.

Fast delivery

Plate heat exchangers are made in Denmark and picked up directly from the factory - no unnecessary logistics steps, no delays.This ensures fast delivery.

Professional service

We offer technical support, professional maintenance services, and factory warranty to ensure the reliable and long-lasting operation of your heat exchangers.

Our Products

Plate Heat Exchangers

We are a sales and distribution partner for gasketed plate heat exchangers, brazed plate heat exchangers, free-flow plate heat exchangers, condensers and evaporators, semi-welded heat exchangers, double-wall heat exchangers, and plate-and-shell heat exchangers, made from materials such as stainless steel and titanium, ensuring optimal heat transfer and a long service life.

Gasketed plate heat exchangers are a highly efficient solution for industrial applications where reliability, easy maintenance, and optimal heat transfer are essential. Thanks to their modular design, they can be quickly disassembled, cleaned, and adapted to the specific requirements of any project.

This type of heat exchanger delivers excellent performance across a wide range of temperatures and pressures, making it suitable for heating and cooling systems, energy installations, and process industries. The gasketed construction simplifies servicing and extends the operational lifespan of the system.

SonFlow plate heat exchangers are designed according to the highest industrial standards and allow easy adjustment of the number of plates to match the application’s needs. This ensures flexibility, high energy efficiency, and long-term cost savings.

Brazed plate heat exchangers are a compact and efficient solution for industrial systems where reliable operation under high pressure and stable temperature conditions is essential. Thanks to their brazed construction, they provide excellent heat transfer in minimal space and require no regular service or maintenance.

This type of heat exchanger is particularly suitable for heating and cooling installations, glycol systems, air conditioning, heat pumps, and other applications where high energy efficiency and reliability are crucial. The absence of gaskets eliminates the risk of leaks, reduces operating costs, and extends the system’s service life.

SonFlow brazed plate heat exchangers stand out with their compact dimensions, optimized hydraulics, and durability under demanding operating conditions. This makes them an excellent choice for projects with limited space and high performance requirements.

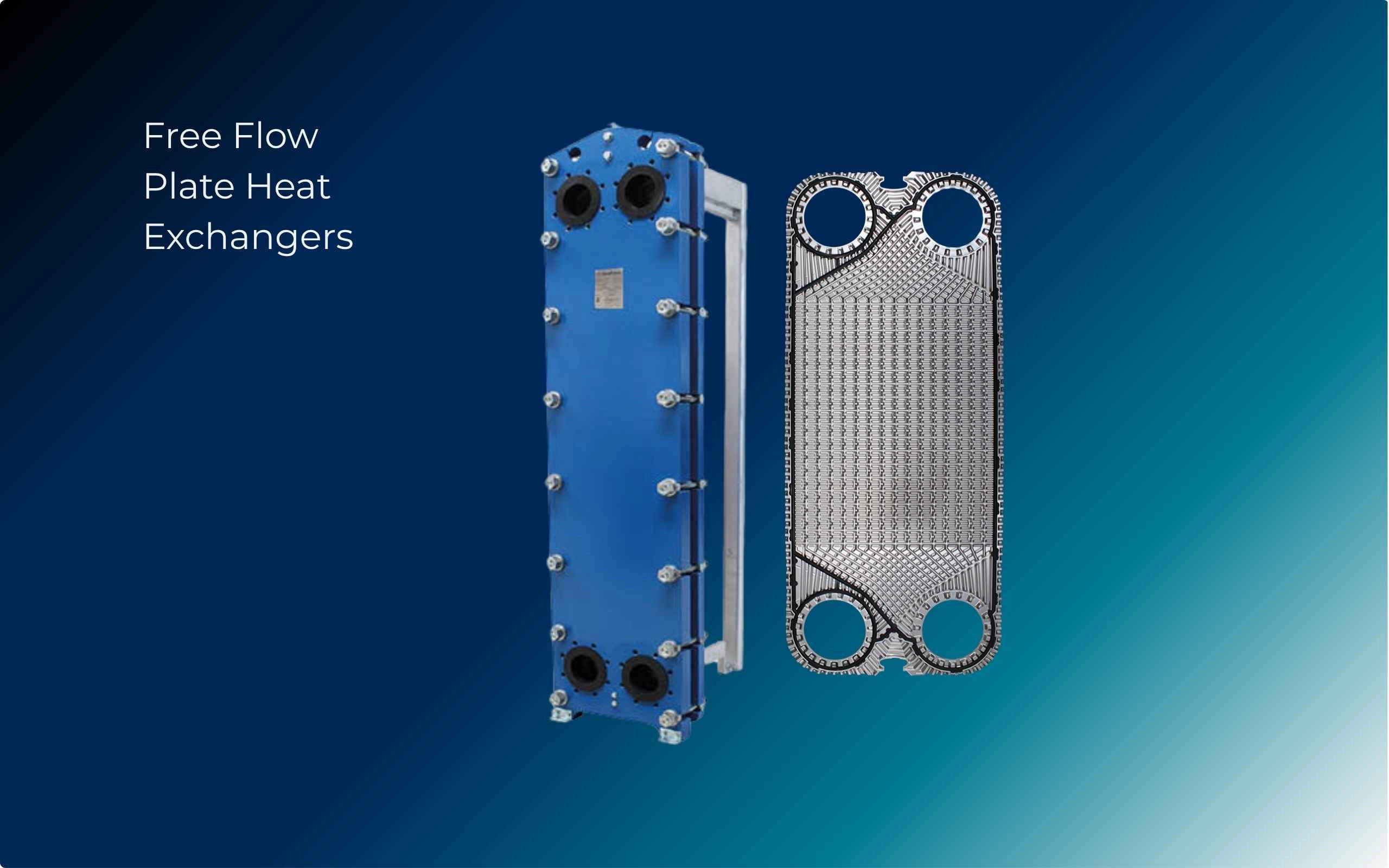

Free Flow plate heat exchangers are specifically designed for industrial applications involving fluids with a high content of impurities, fibers, or particles. Thanks to the open channel design between the plates, this type of heat exchanger eliminates the risk of clogging and ensures stable heat transfer even under the most demanding conditions.

The Free Flow construction is ideal for processes in the food and beverage, processing, chemical, and energy industries, as well as for applications with unfiltered or viscous fluids. With no turbulence zones and a larger hydraulic cross-section, these heat exchangers provide low pressure drop and high energy efficiency.

SonFlow models deliver reliable performance, easy maintenance, and long service life. They are designed in accordance with industrial standards for durability and safety, making them an excellent solution for environments with increased demands on reliability and efficiency.

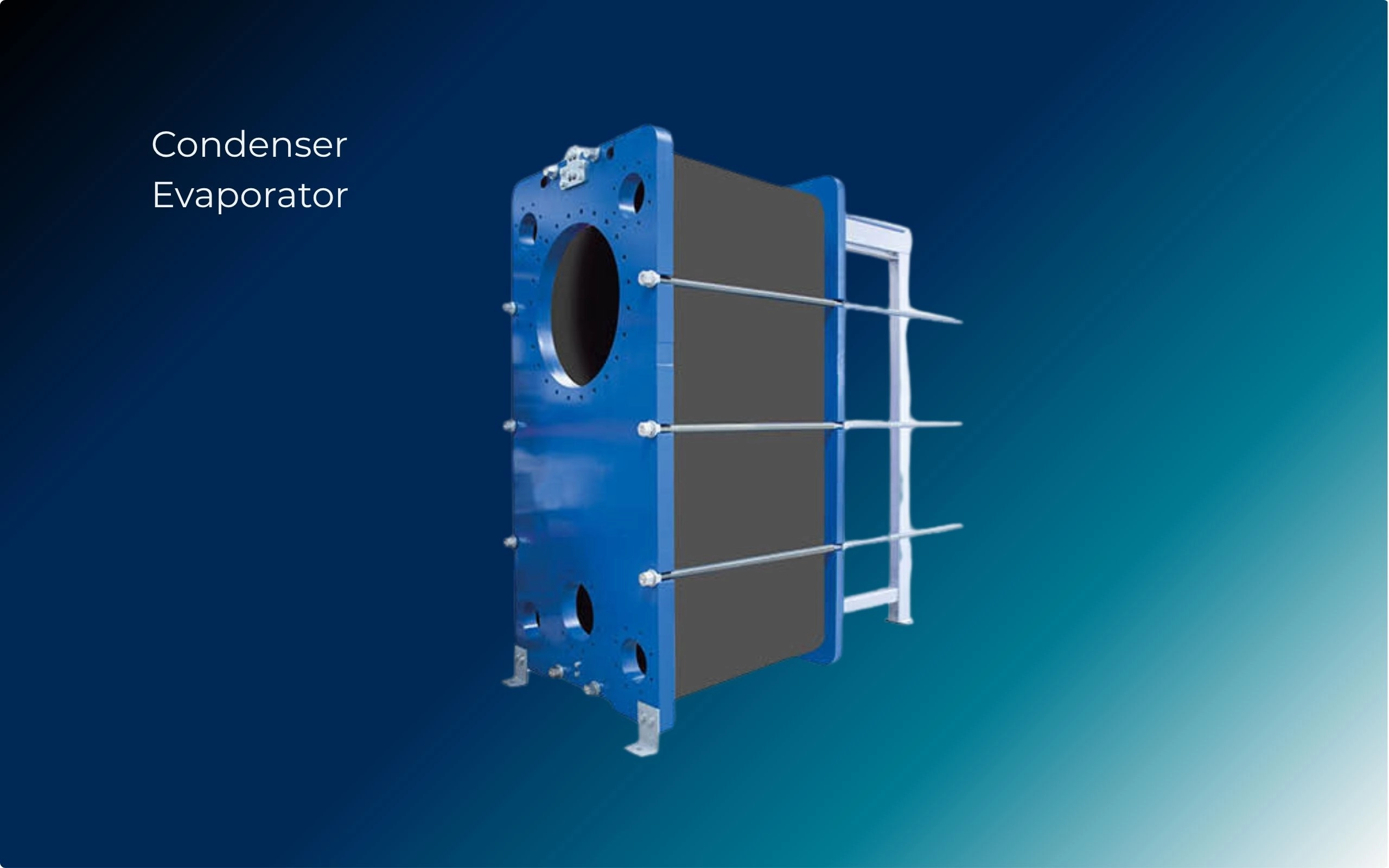

Industrial plate heat exchangers of the Condenser/Evaporator type are designed for the most demanding technological processes. SonFlow models are specifically developed for condensing low-pressure steam and for evaporation under conditions of high temperature and pressure differentials.

These systems are ideal for industries such as food and beverage, sugar production, biogas, pulp and paper, mining, chemical, petrochemical, and alcohol processing.

Their main advantages include specially engineered plates with asymmetric flow — a large steam inlet and a smaller cooling water and condensate inlet/outlet — ensuring optimal heat transfer.

If you are looking for a premium solution for heavy-duty industrial heat transfer processes, explore our range of industrial plate condensers and evaporators — designed for high loads, maximum efficiency, and continuous operation under critical conditions.

NEW: Semi-welded Plate Heat Exchangers, Double-wall Heat Exchangers, Plate-and-shell Heat Exchangers

Double-Wall Heat Exchangers

Providing the highest level of operational safety, our Double-Wall heat exchangers are designed to prevent cross-contamination and ensure reliable performance. Key features include:

- Maximum safety – prevents media mixing

- Welded construction for strength and durability

- Reliable long-term performance you can trust

Plate-and-Shell Heat Exchangers

Plate-and-Shell heat exchangers are designed to deliver reliable performance under extreme conditions. The SFPS will be available in two models, SFPS50 and SFPS100, with additional variants planned for future release. Key features include:

- Reliable performance through laser-welded cassettes

- Handles extreme temperatures and pressures

- Outstanding performance for condensation and evaporation

Semi-Welded Plate Heat Exchangers

Ideal for aggressive media and challenging duties, Semi-Welded plate heat exchangers combine strength and efficiency. Key features include

- Perfect for challenging duties with aggressive media

- Laser-welded cassettes for maximum strength

- High efficiency and easy CIP-cleaning

Select a plate heat exchanger

Send us your inquiry and we’ll help you choose the right solution.

Choose the right heat exchanger and build an efficient, durable, and cost-effective system tailored to your project’s needs. Our product range includes solutions for a wide variety of applications — from standard water installations and heat pump systems to fluid cooling, circuit separation, process heating, and industrial production lines.

Whether you need a solution for HVAC, refrigeration systems, or heavy industrial processes, you’ll find the right model for your application. Our heat exchangers comply with the highest industry standards and offer the flexibility needed for seamless integration into any technological environment.

We offer plate heat exchangers with different construction types — gasketed, brazed, Free Flow, condenser/evaporator units, and semi-welded shell & plate systems. Every model is designed for high energy efficiency, reliable operation, and a long service life.

Choose your heat exchanger online and request a quote in just a few clicks — fast, easy, and professional.

Industrial pumps

Our pumping solutions are designed to deliver reliable performance, high efficiency, and a long service life across a wide range of industrial applications. We offer a comprehensive selection of pumps tailored to the needs of sectors such as water supply, energy, marine, construction, mining, and processing industries.

Each model is engineered to operate reliably under high loads and challenging conditions, ensuring optimal flow rates, low operating costs, and easy maintenance.

- Wastewater pumps

- Industrial and Marine Inline Pumps

- End Suction Industrial and Marine Pumps

- Drainage, sand and slurry pumps

High-quality heat transfer solutions with direct delivery from the factory

Over 45 years of experience in heat exchanger technologies. Certified products.

Whether you operate in heating, air conditioning, refrigeration, food and beverage, marine and shipbuilding, or any industrial production sector, our mission is to provide you with the best heat transfer and pumping solutions.

Contact us today to discuss how we can support your business with our plate heat exchangers and industrial pump solution.

Why engineers and contractors in Greece, Romania and Cyprus choose KONTECH

KONTECH supplies SonFlow plate heat exchangers to HVAC contractors, industrial engineers and project developers across Southeast Europe.

Our clients in Greece, Romania and Cyprus choose us for:

-

Pricing based on project parameters, quantities, and required lead time

- Support with selecting a suitable plate heat exchanger for HVAC and industrial installations, based on the data provided

- Fast quotation preparation, subject to complete input data

-

Estimated lead times and order status updates, subject to stock availability and production schedules

- Long-term spare parts availability for gasketed models, subject to the manufacturer’s product policy

Contacts

Service point address:

Bulgaria, BG - 1700, Sofia, Lozenets District