en

en

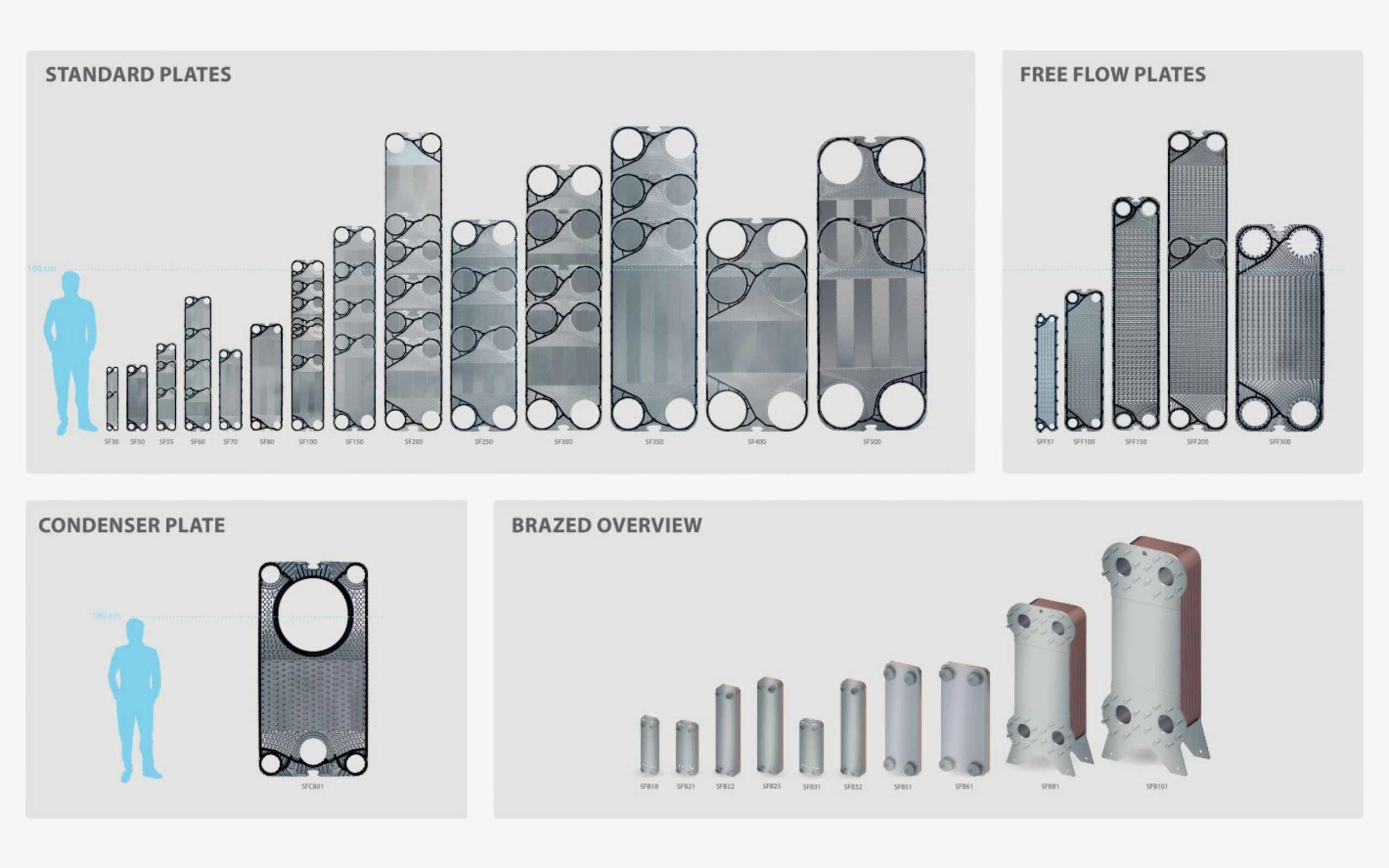

Plate heat exchangers SonFlow

SonFlow A/S offers high-quality plate heat exchangers. The heat exchangers are optimized to meet specific temperature demands and capacities in HVAC, industrial or sanitary applications. They feature with:

- Danish design, technology, and quality

- Competitive prices

- Short lead times

- Advanced supply chain capabilities

- Traceable production processes ensuring quality

- Full monitoring of raw materials

The production and assembly of the heat exchangers are carried out at SonFlow's modern facility in Kolding, Denmark.

Advantages of SonFlow plate heat exchangers:

- Разглобяема конструкция

- Expandable

- Easy to clean

- Compact size

- Less fouling

- Lower costs

- High efficiency

Technical specifications:

- Connections from DN25 to DN400

- Frames designed according to PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards

- Plate materials: AISI 304/316, titanium, SMO. Other materials available upon request

- Gasket materials: EPDM, NBR and Viton.

- Plate heights up to 3.5 m

- Flow rates up to 7200 m³/t

- Working pressure up to 25 bar

Technical specifications:

- Plate material: AISI 316

- Brazing material: Copper

- Design pressure: 25 and 40 bar

- Temperature: -100˚C to 185˚C

- Connections: between ¾” and DN100

SonFlow offers a comprehensive range of specialized heat exchangers that provide unrestricted fluid flow through the wide channels of the plates, which do not come into contact with each other, thus ensuring efficient heat transfer. The distance between each pair of plates can be up to 12 mm, depending on the type of plate.

These heat exchangers are suitable for fluids containing solid particles, with a high fiber content, or with high viscosity.

Приложими за флуиди, които съдържат твърди частици, имат богато съдържание на фибри или са с висок вискозитет.